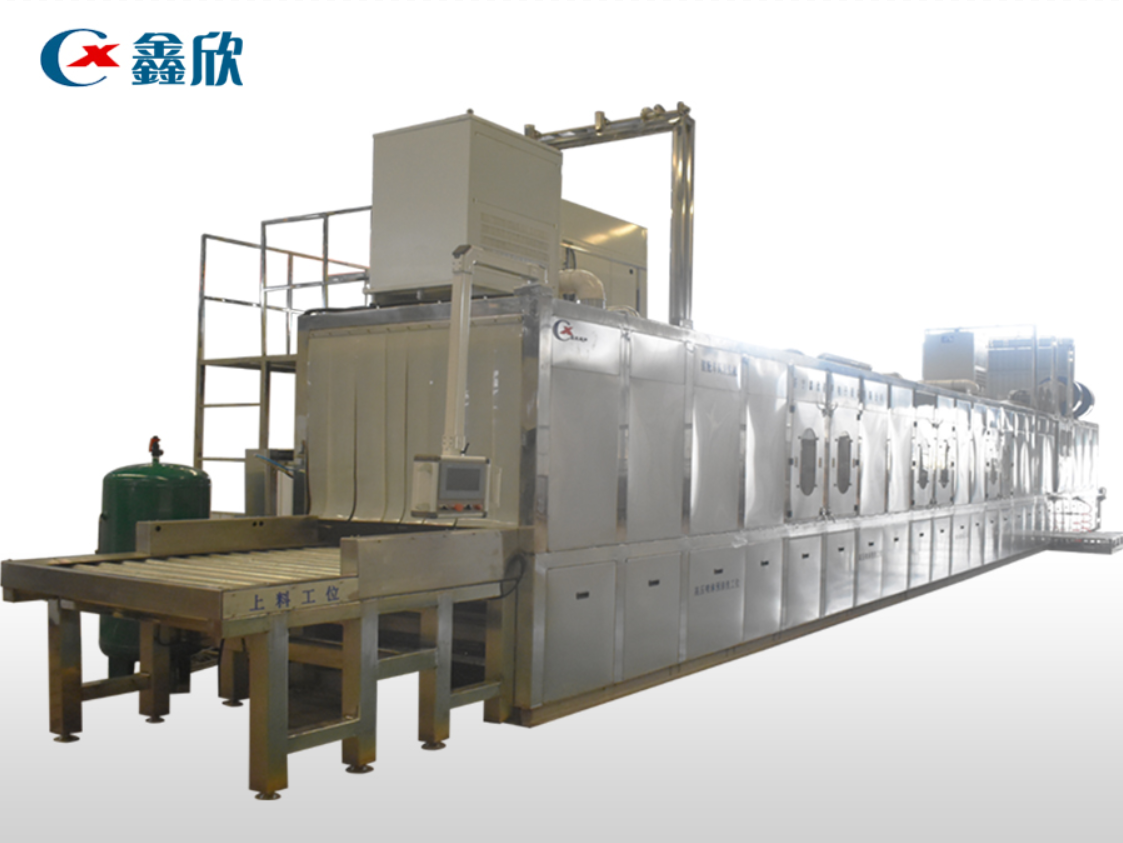

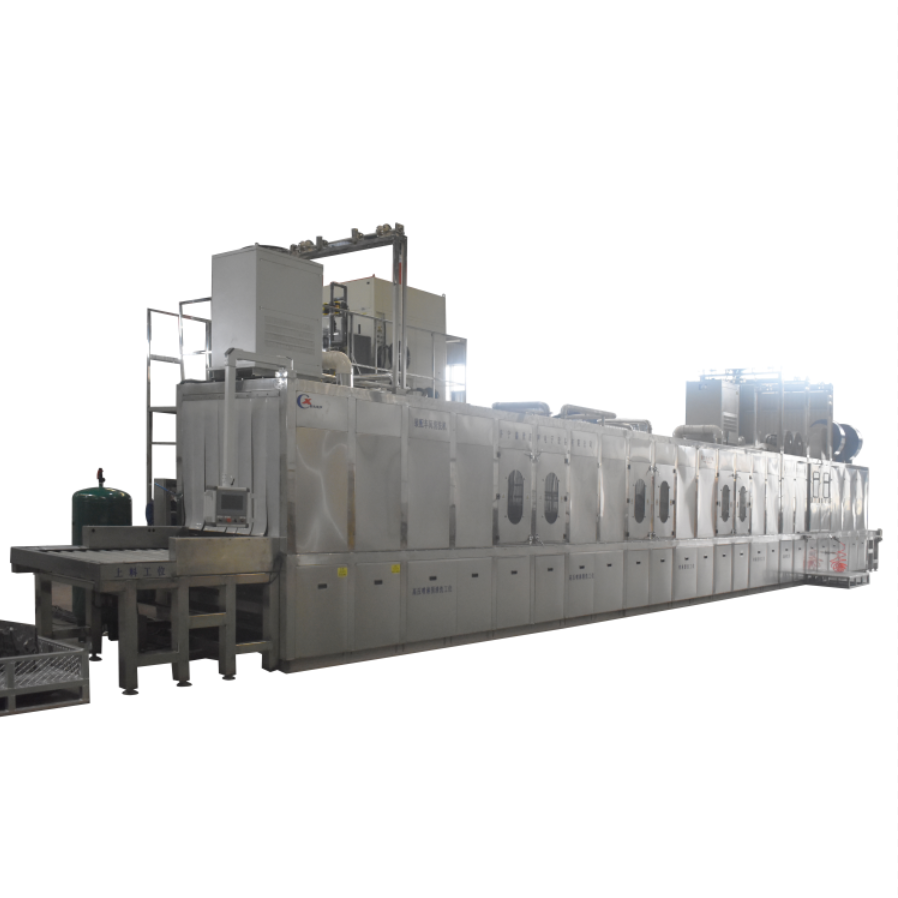

(01) Set the operating parameters of the equipment through the touch screen on the device, manually place the workpiece and accompanying material frame at the loading station using the overhead crane, and automatically transport the material frame to the spray cleaning station through the empty space. → (02) Enter the spray pre cleaning station, and the spray pipeline begins to spray clean. The cleaning solution uses cleaning agent and municipal water to effectively clean the dirt on the workpiece. After the spray pre cleaning is completed, the material frame is automatically transported to the spray fine cleaning station through the empty space, and the spray pipeline starts high-pressure spray fine cleaning to further rinse the workpiece. After the high-pressure spray cleaning is completed, the equipment is automatically transported to the spray rinsing station through the empty space, and the spray rinsing begins. Clean municipal water is used for rinsing. After rinsing, the equipment automatically transports the empty space to the spray rust prevention station for spray rust prevention cleaning. After the spray rust prevention is completed, the equipment runs to the high-pressure air cutting station to cut off the water droplets on the surface of the workpiece and shorten the drying time of the workpiece. After the high-pressure air cutting is completed, the workpiece automatically runs to the manual cleaning and blowing station for manual cleaning and blowing. After manual cleaning and blowing, perform high-pressure hot air cutting and drying. After the high-pressure hot air cutting and drying are completed, the workpiece is automatically transported to the unloading station and manually unloaded from the pallet using a crane.

| Previous:Wheel hub continuous pass cleaning machine | Next:Wheel hub continuous pass cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact