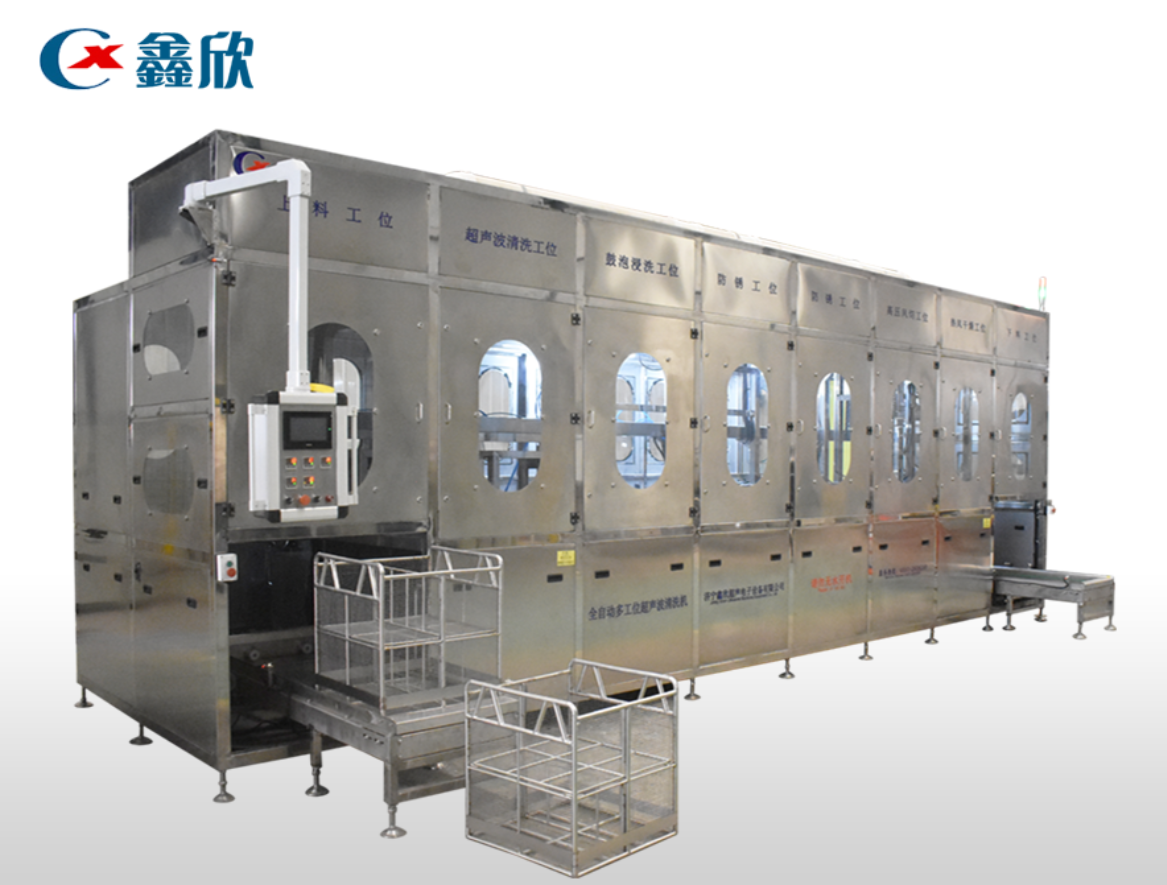

Process: 1. Workers load the parts into the material frame and place them in the loading area of the automated cleaning equipment. The robotic arm automatically grabs the parts. → 2. The mechanical arm of the equipment lifts the material frame from the feeding area and places it in the ultrasonic immersion tank, completely immersing the material frame in the cleaning solution and performing the ultrasonic immersion process. After ultrasonic immersion, the robotic arm grabs and places compressed air through the bubbling device at the bottom of the tank to generate a large number of bubbles, increasing the flow rate between the liquid and the workpiece surface. After the bubble cleaning is completed, the robotic arm grabs the workpiece and immerses it into a tank containing anti rust solution. There are anti rust tanks for steel and aluminum parts respectively, which are selected by the worker. After the rust prevention tank is completed, the mechanical arm grabs and enters the furnace body to set up multiple air knives that can blow out compressed air. The air knives can swing back and forth to thoroughly dry the workpiece through air cutting. After the high-pressure air cutting is completed, the robotic arm grabs it to the drying station. The air passes through the circulating fan and air heater and becomes hot air to blow towards the parts, achieving the effect of no water accumulation on the surface of the parts and drying. 7. The mechanical arm of the equipment places the material frame in the unloading area, and workers unload the material from the frame and clean it.

| Previous:Wheel hub continuous pass cleaning machine | Next:Wheel hub continuous pass cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact