(01) Control the operation and stop of the entire machine by setting various parameters for device operation through the touch screen on the device. Manually place the fixture containing the workpiece on the loading station, and the operator presses the start button;

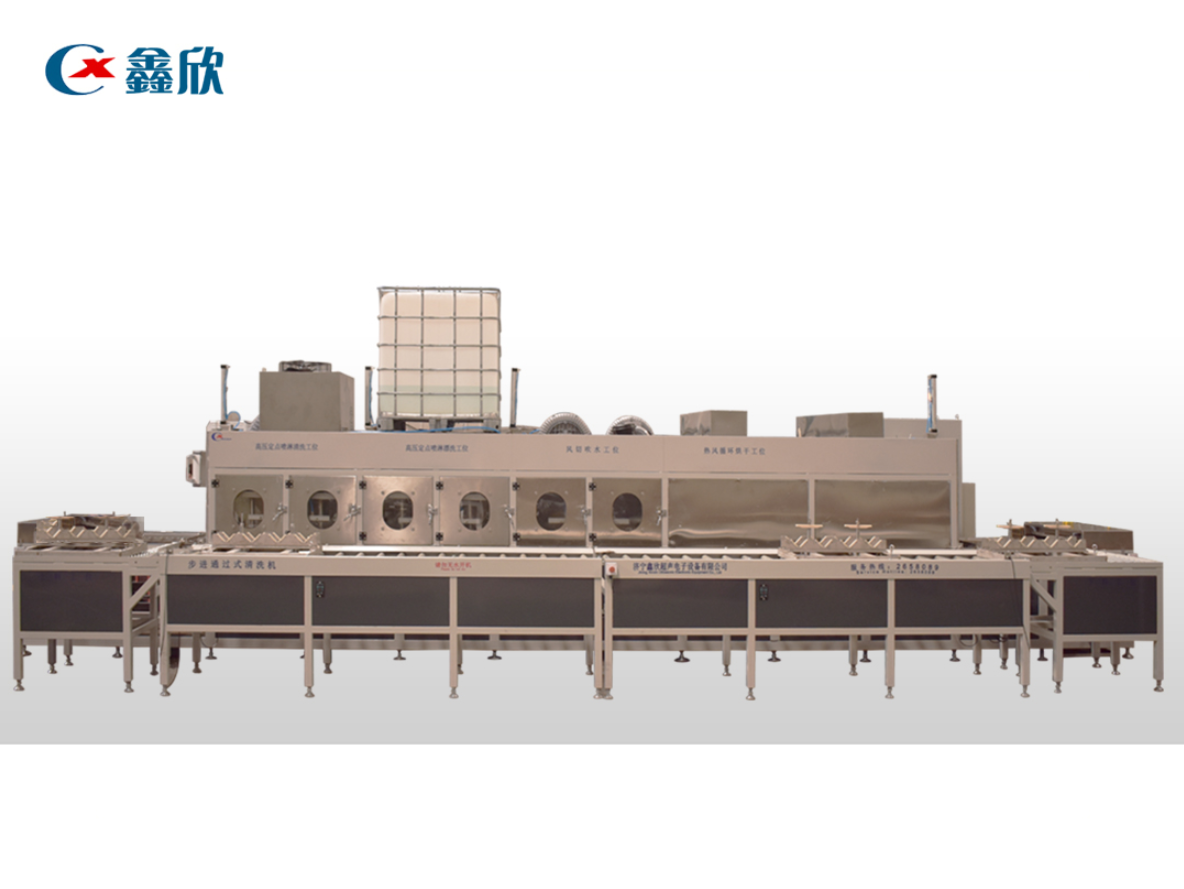

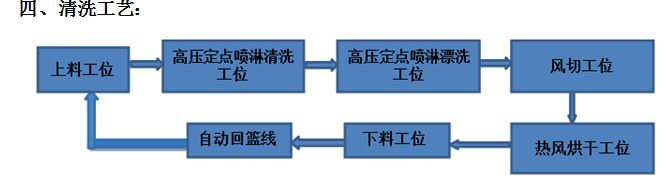

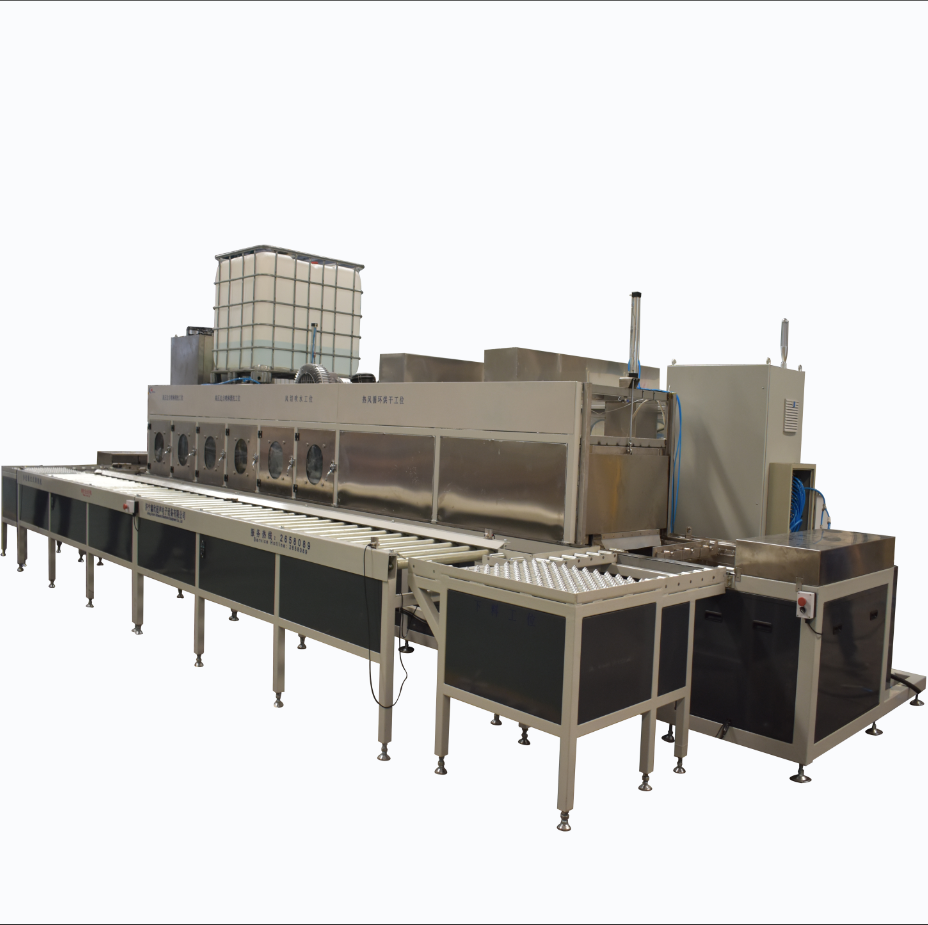

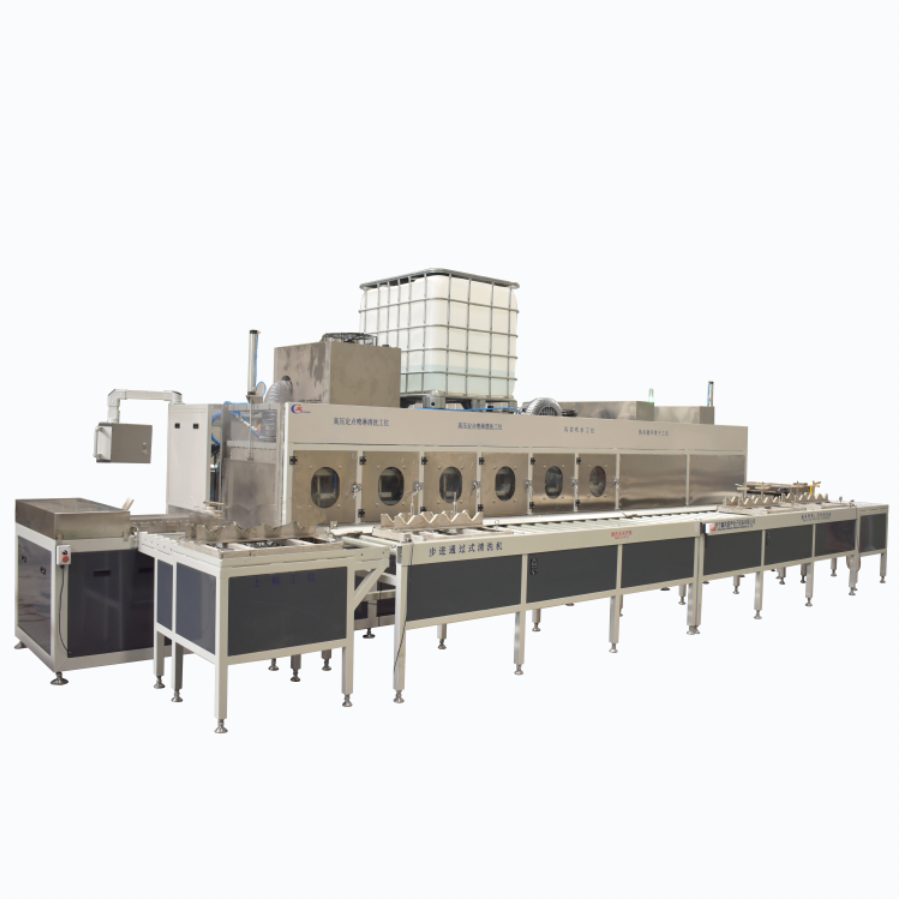

At the loading station, the equipment operating device automatically moves the workpiece to the high-pressure fixed-point spray cleaning station for high-pressure fixed-point spray cleaning. There is a circular stainless steel nozzle in the cleaning room, which is installed on the top, bottom, and side of the spray pipe. The angle of the nozzle can be adjusted. The side positioning spray device (nozzle extends into the inner chamber) performs positioning spray cleaning on blind holes of the workpiece, while the upper and lower nozzles (fan-shaped) simultaneously flush the surface of the workpiece. Thus, the stains on the inner and outer surfaces of the workpiece can be removed → (03) After the high-pressure fixed-point spray cleaning is completed, the equipment operating device automatically moves the workpiece to the high-pressure fixed-point spray rinsing station for fixed-point high-pressure spray rinsing. The nozzle is installed on the top, bottom, and side of the spray pipe, and the angle of the nozzle can be adjusted. The side positioning spray device (nozzle extends into the inner chamber) performs positioning spray cleaning on blind holes of the workpiece, while the upper and lower nozzles (fan-shaped) simultaneously flush the surface of the workpiece. The main function of this workstation is to thoroughly remove residual stains and cleaning agents on the surface of the workpiece, and improve the cleanliness of the workpiece surface. After the high-pressure fixed-point spray rinsing is completed, the equipment operating device automatically moves the workpiece to the high-pressure air cutting station, where mobile air cutting and water blowing are carried out. The air brush adopts stainless steel air brush, and the gap between the air brush outlet and the water cutting angle can be adjusted. Wind can cut off water droplets on the surface and inside the cavity of the workpiece. After the high-pressure air cutting is completed, the equipment operating device automatically moves the workpiece to the drying station. Hot air drying uses a hot air fan and an electric heater to quickly dry the workpiece. After the workpiece is dried, the equipment running device automatically moves the workpiece to the cutting station for cutting.

| Previous:Wheel hub continuous pass cleaning machine | Next:Wheel hub continuous pass cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact