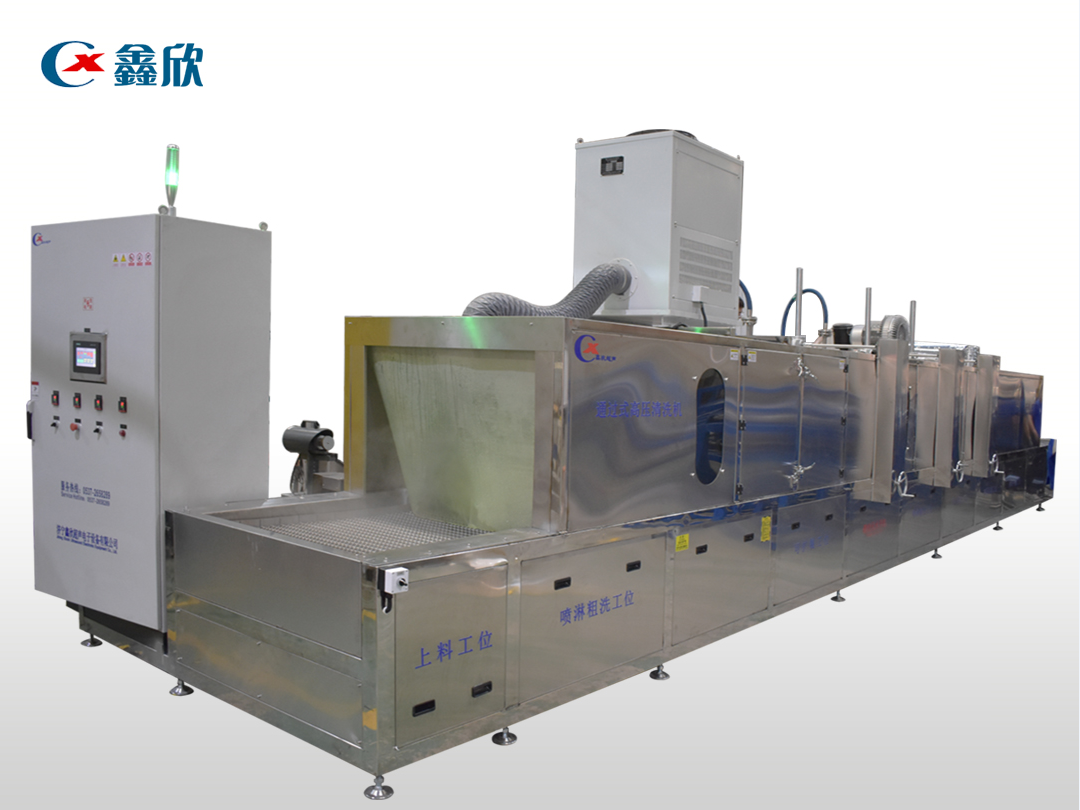

Description: The equipment consists of loading and unloading stations, spray coarse washing system, expandable space, spray fine washing system (adjustable), spray rinsing system (adjustable), high-pressure air cutting system (adjustable), hot air drying system, cooling station, transmission system, pipeline system, electrical control system, etc. The equipment has good cleaning effect, fast drying speed, reasonable structural design and process arrangement, high degree of automation, and high cleaning accuracy Avoiding contamination from secondary loading and unloading of workpieces.

(01) Set all parameters, manually load the workpiece to be cleaned into the cleaning material frame and place it on the conveyor belt. The conveyor belt first transports the workpiece to the cleaning station and starts spraying coarse washing → (02) After reaching the set cleaning time, the spraying coarse washing is completed, and the conveyor belt moves to send the workpiece to the spraying fine washing station (which can adjust the position of the upper spray according to the height of the workpiece) → (03) After the spraying fine washing is completed, the conveyor belt transports the workpiece to the spraying rinsing station (which can adjust the position of the upper spray according to the height of the workpiece) → (04) After reaching the set rinsing time, stop rinsing and transfer the workpiece to the high-pressure air cutting station (which can adjust the upper spray according to the height of the workpiece) position), the wind blows away water stains on the surface of the workpiece → (05) After wind cutting, The workpiece is transported to the drying station for rapid drying → (06) After drying, the workpiece enters the cooling station and is transported to the unloading station for manual removal and unloading.

| Previous:Wheel hub continuous pass cleaning machine | Next:Wheel hub continuous pass cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact