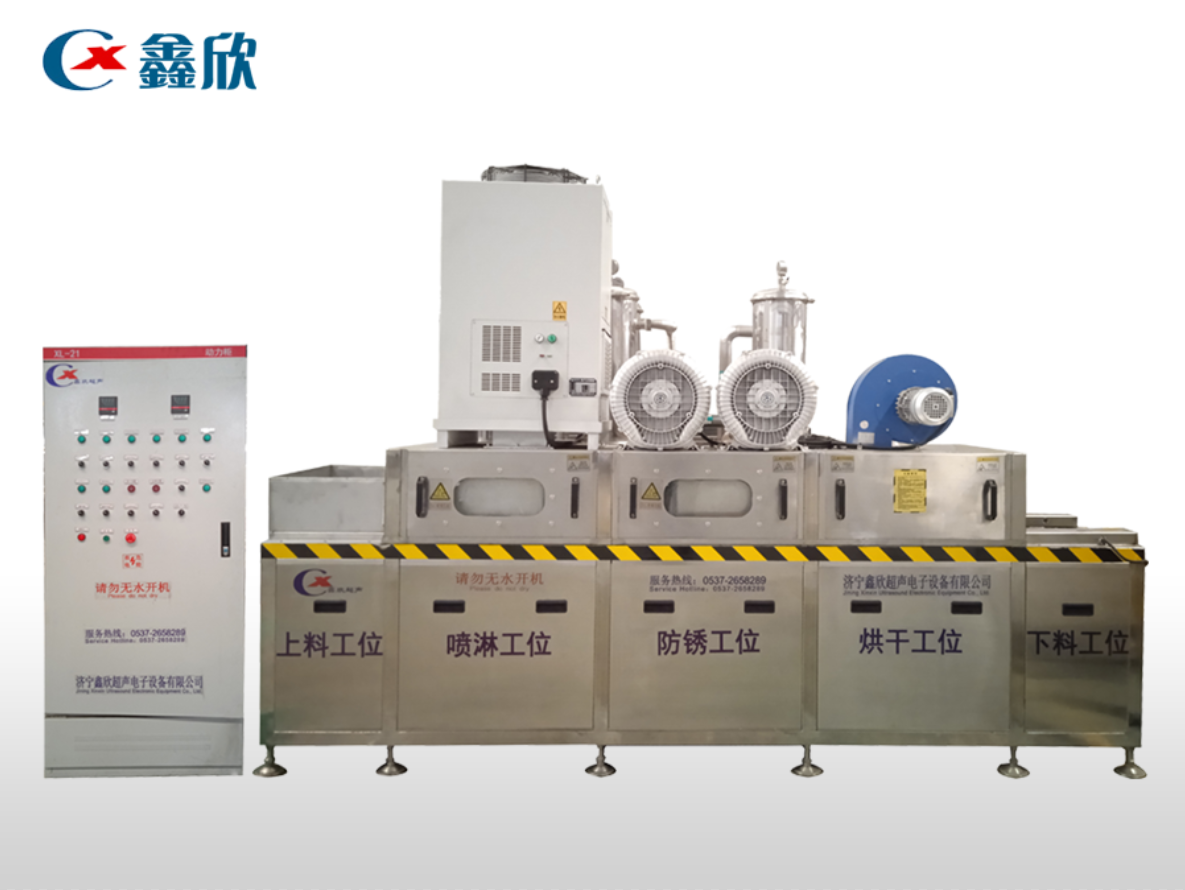

The equipment consists of loading and unloading mesh belts, spray cleaning stations, spray rinsing stations, high-pressure air cutting, hot air drying stations, temperature controlled water heating systems, fans, temperature controlled air heating systems, PLC+touch screen control systems, pipeline systems, and intelligent electrical control systems. The automatic liquid inlet and outlet and automatic heating system have completely achieved unmanned intervention and automatic operation, greatly reducing the labor intensity of workers. The advanced mist treatment system can condense and reflux the mist generated during cleaning, and the air is filtered and adsorbed by activated carbon before being discharged.

The equipment is equipped with an advanced remote diagnostic system, which can enable equipment manufacturers to remotely detect equipment failure points and quickly repair them. At the same time, MS and PROFINET interfaces are also configured for easy interaction and docking with other production lines

| Previous:Wheel hub continuous pass cleaning machine | Next:Wheel hub continuous pass cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact